BotsIQ Teams Tour Miller Fabrication

February 24, 2023

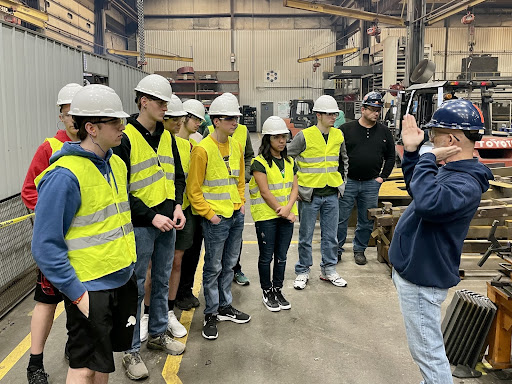

On Thursday, February 23rd, our BotsIQ teams had the opportunity to visit and tour Miller Fabrication Solutions, located in Brookville, Pa. This trip was only available to students that are a part of the Advanced Fabrication Robotics and Advanced Programming Robotics students. Paul Smith, Mackenzie Thomas, Tucker Penrose, Chase Koches, A.J. Lynn, Nathan Druschel, Daniel Waltermire, Ryan Dicken, and J.J Ferraro all spend the day learning about careers in the manufacturing industry, seeing all of the concepts they’re using in the classroom used in a real-world setting, and ultimately collecting knowledge in order to make sure that their combat robots will be the best they can be for their upcoming competition.

Miller Fabrication Solutions is one of the most successful metal fabrications in the United States, ranking 23rd on the FAB 40 in 2022. Across their 3 locations, they employ over 300 hundred people, including machinists, programmers, and engineers. All of which, are careers that potentially interest members of our teams. Some of their services include welding, coating and finishing, and mechanical assembly. The mission of the company is to operate in a clean, quality, and safe environment, while also making sure to keep production moving as much as possible.

The manufacturing progress that they had the opportunity to witness on the tour opened their eyes to how much it related to designing, building, and documenting a robot for BotsIQ. Early in the tour, they had the opportunity to meet with the company’s lead robotic programmer. Similar to how they program the plasma cutter to create parts, he illustrated to the team how he used his cutting-edge software to efficiently design, and have parts created with robots. They saw a machine that is used for bending metal, and one of our teams noted that using a machine similar to that would have perhaps been more effective than welding the corners of their bot. Later in the tour, the students were able to experience first-hand many machines creating large parts, similar to the parts that they create just on a much larger scale.

After completing the tour, the team members asked the tour guides many clarifying questions, pertaining mostly to the schooling they needed to be employed in an industry of that caliber. Following the insight, some of the students are now considering careers in computer and mechanical engineering. As a whole, the teams have gained an entirely different respect and understanding of manufacturing, as well as the men and women who are employed by manufacturing companies. Ultimately, the industry tour was a worthwhile experience!